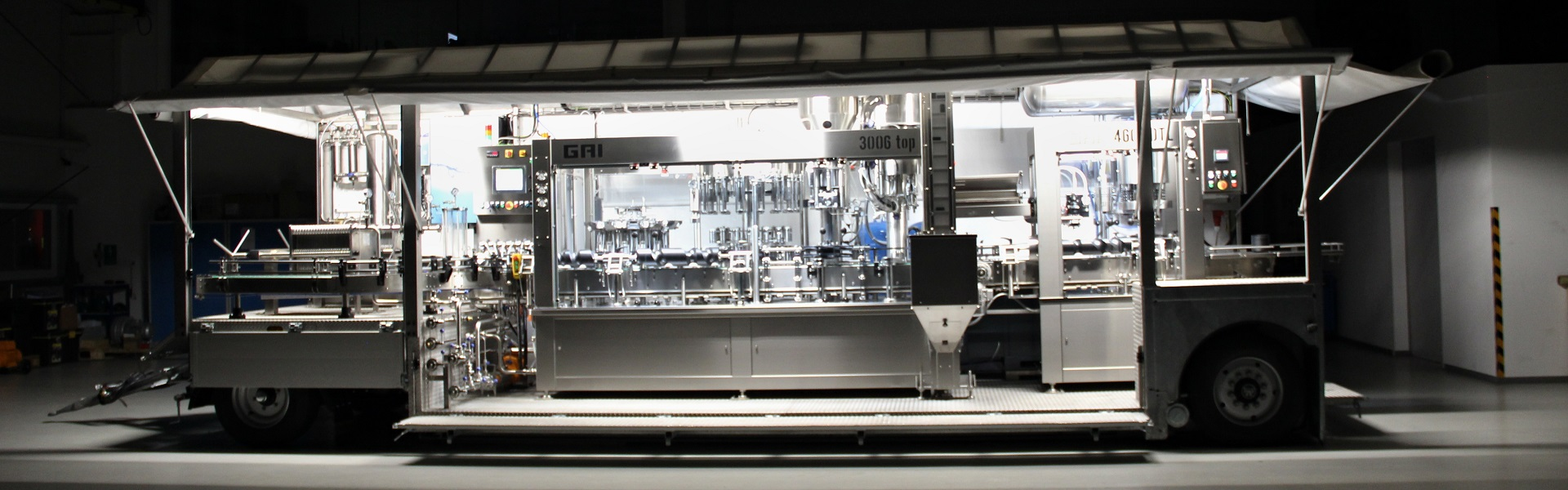

MULTIWRAP 130

SPEED AND PERFORMANCE

The Multiwrap 130 was born combining the Mascar experience in the round balers and in the wrappers fields and it is the ideal machine for harvesting green products. You can do at the same time the pick-up phase and the wrapper one, halving working times and costs avoiding this way further contamination due to contact with the ground.

FEED

Cutting rotor with 15 or 25 knives “CUT.25” to maximize chopping.

CONTROL AND MANAGEMENT

Directly from the tractor cab, through the user-friendly automotive control terminal, the operator can select the bale pressure level and constantly supervise the work of the round baler.

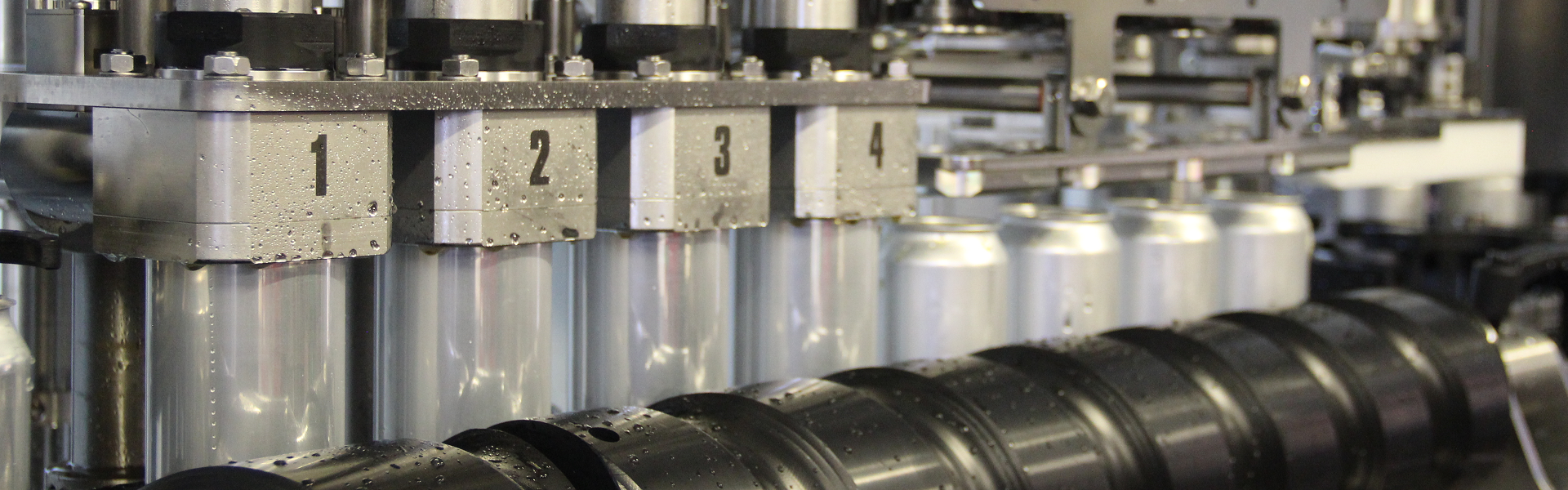

WRAPPING

The dual arm wrapping system completes the work process with a uniform and fast distribution of the film on the entire surface of the bale to obtain a perfectly sealed product for the benefit of a superior silage quality.

TECHNICAL SPECIFICATIONS

| Model | MULTIWRAP 130 - MULTIWRAP .25 |

| Chamber | Fixed |

| Bale dimensions (cm) | 120 x 130 |

| Number of rollers | 18 |

| Pick-up width (cm) | 200 |

| Tines row/tines for each row | 4/28 |

| Tine pitch (mm) | 65 |

| Cutting system CUT – CUT. 25 (knives) | 15 (0-15) - 25 (0-12-25) |

| Cutting length (mm) | 70 - 42 |

| Drop floor | Standard |

| Net binding | Standard |

| Double twine binding | Optional |

| Automatic chains lubrication | Standard |

| Centralized greasing system | Standard |

| Semi-automatic greasing system | Optional |

| Tyres | 600/55-22.5 |

| Power supply | 12 V – 20 A |

| Hydraulic tractor requirements | 1xDA , 1xSA + Free return |

| Adjustable drawbar | Adjustable |

| P.T.O. shaft | Homokinetic with overload clutch |

| Minimum required power (Kw (Hp)) | 88 (120) |

| P.T.O. (RPM) | 540 |